elaboro® Biomaterials

elaboro® Dental Ceramics

Synthesis of Function and Esthetics

elaboro® ZIRCONOXIDE

The basis for dentures

elaboro® LITHIUMSILICAT

The ceramic tooth enamel

elaboro® ZIRCONIA

Metal-free Dentures

elaboro® Lithiumsilicat

Ceramic Enamel

for Zirconia Restorations

elaboro® ZIRCONIA Blanks

Maximum Biocompatibility

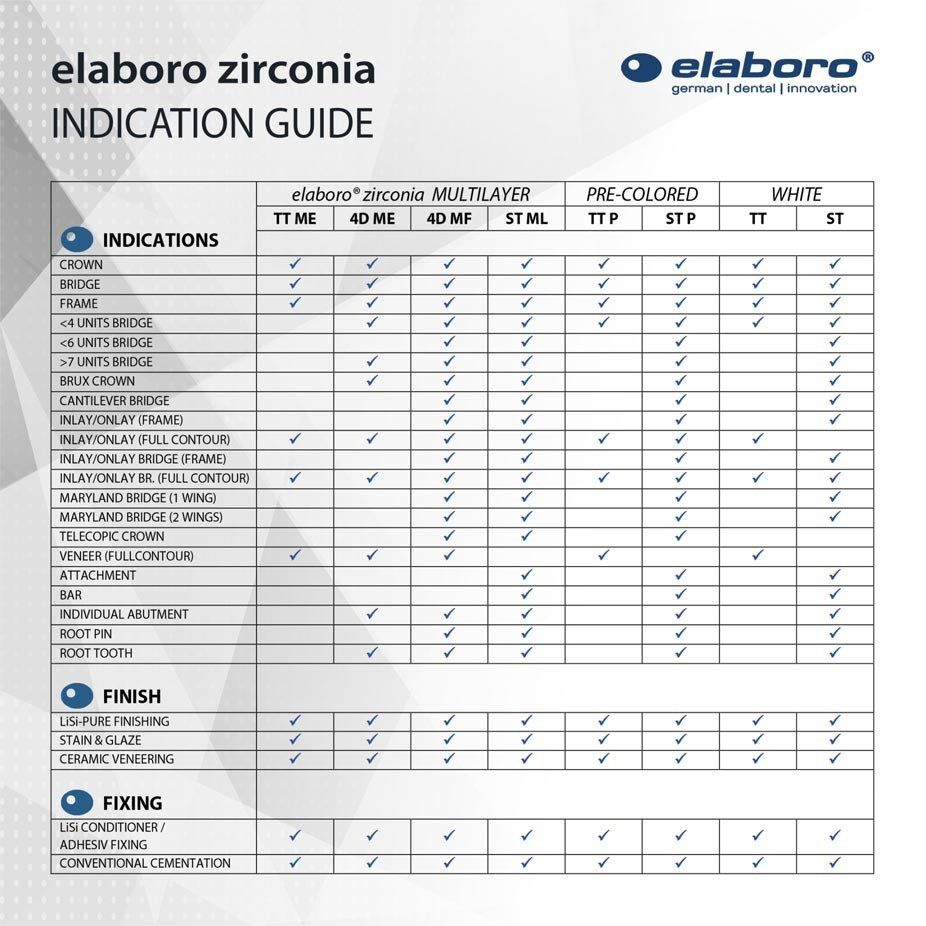

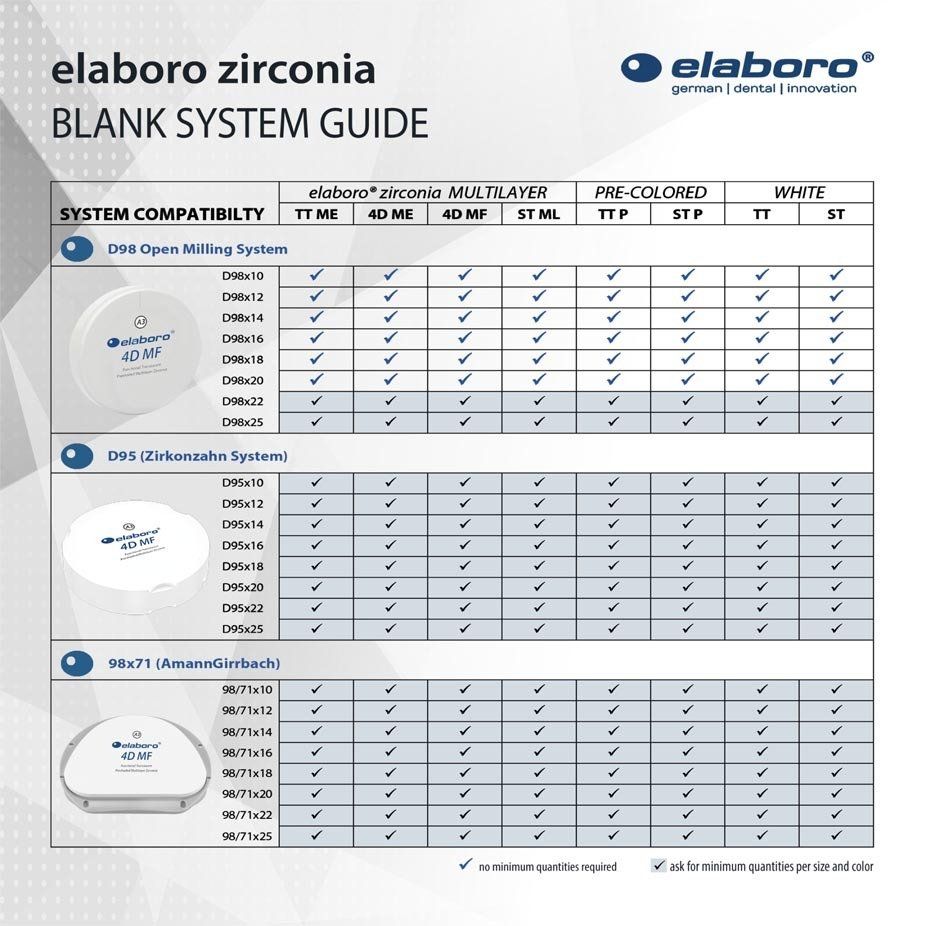

The blanks are produced to order. The possible system configurations can be found in the following overviews.

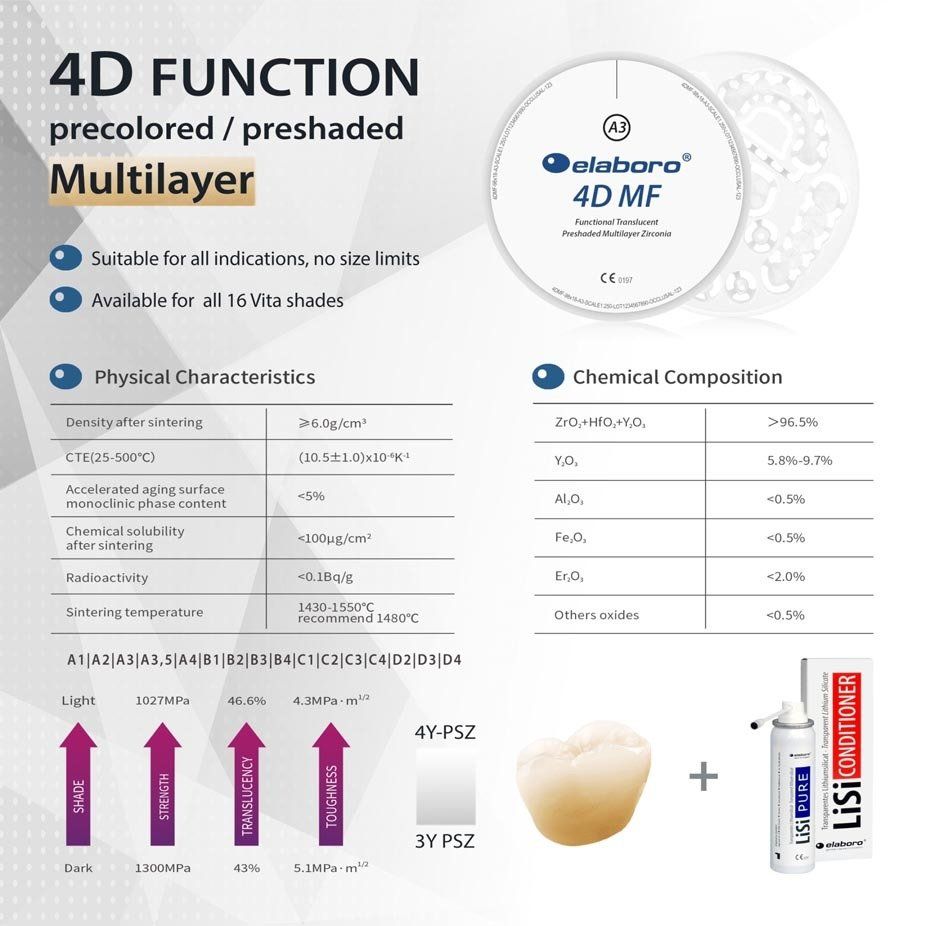

Our MULTILAYER, PRECOLORED and WHITE ZIRCONIA blanks have an excellent price-performance ratio and harmonize optimally with our elaboro® LiSi surface finishes.

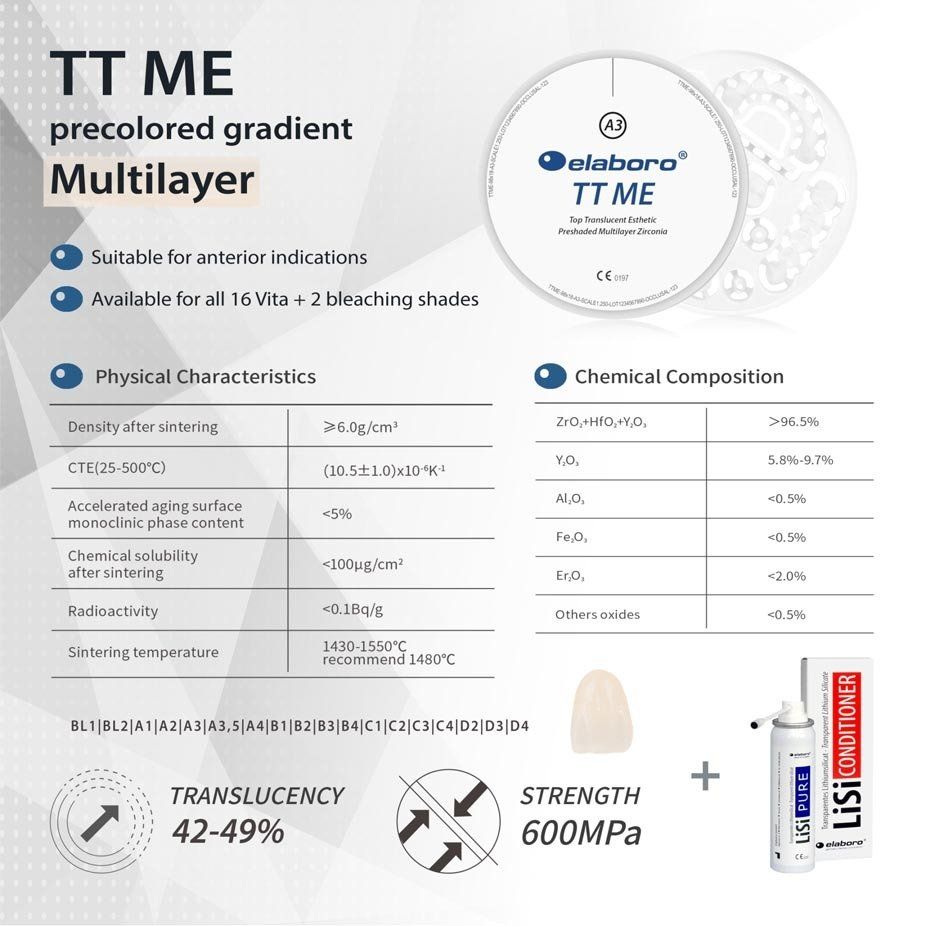

TTME Esthetic Multilayer – our highlight in terms of esthetics.

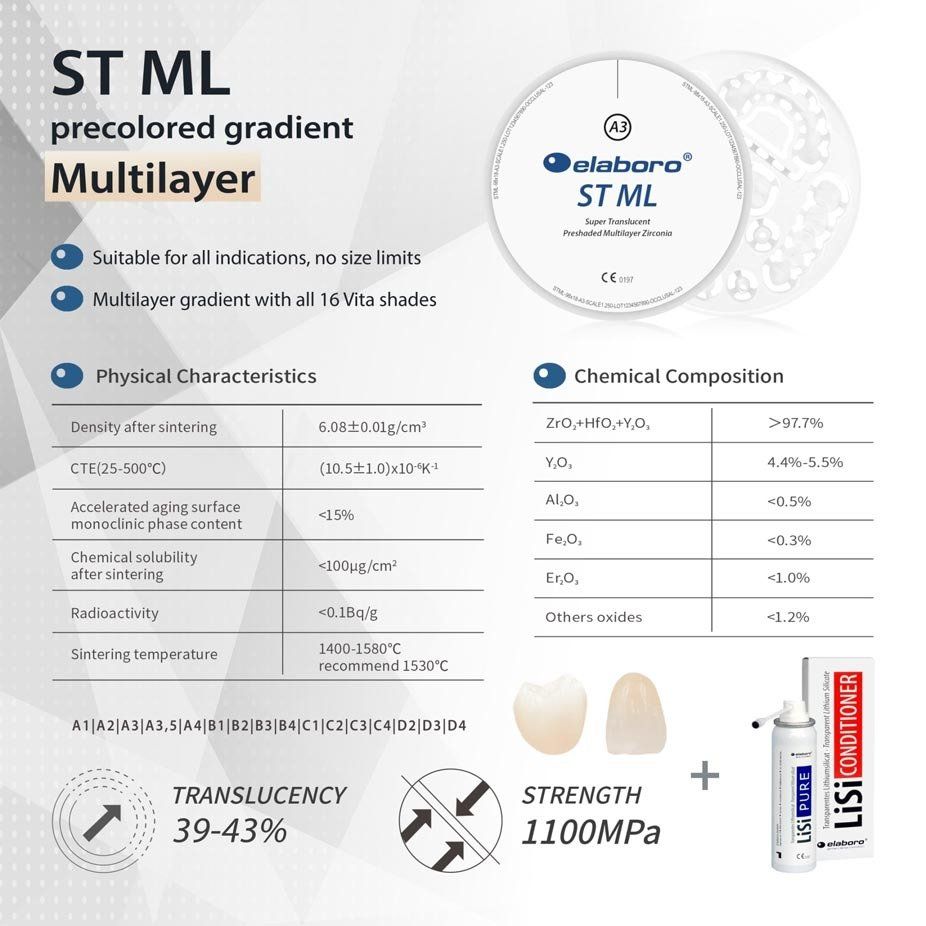

The STML Multilayer is not only suitable for large-span restorations in the posterior region, it can be used universally for full anatomy and for aesthetically demanding frameworks.

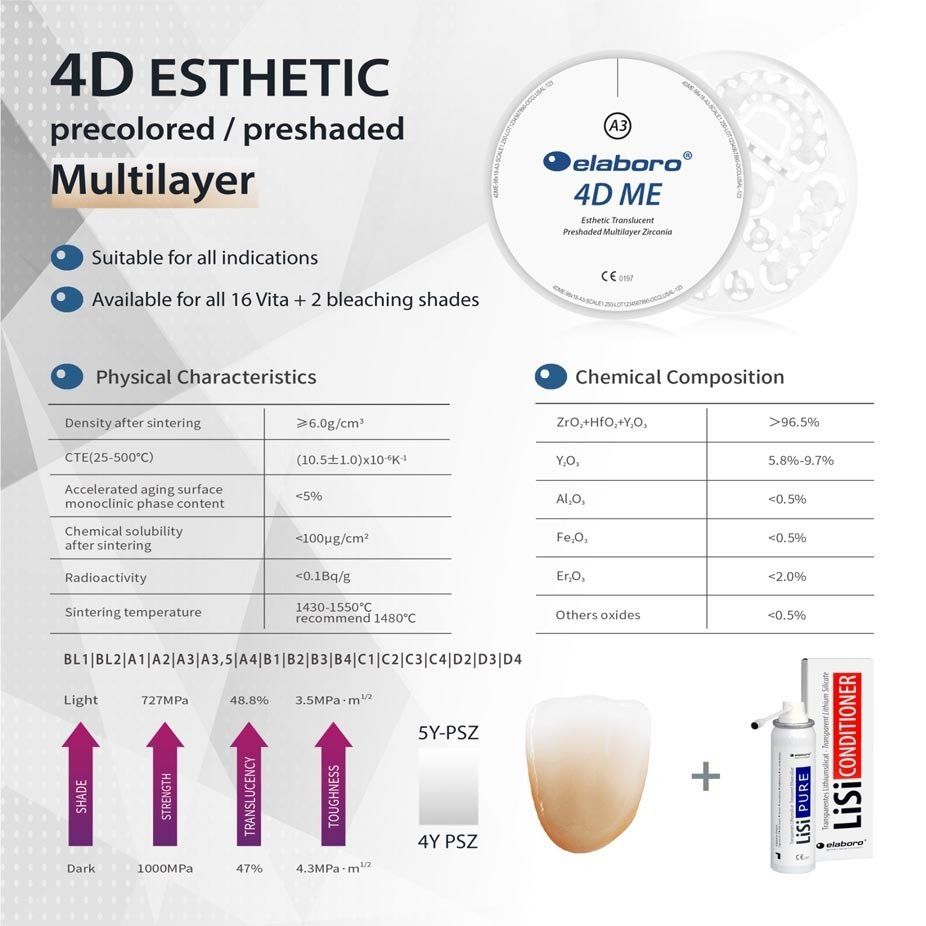

The new 4DME Esthetic Multilayer combines high translucency and maximum strength with a smart color gradient.

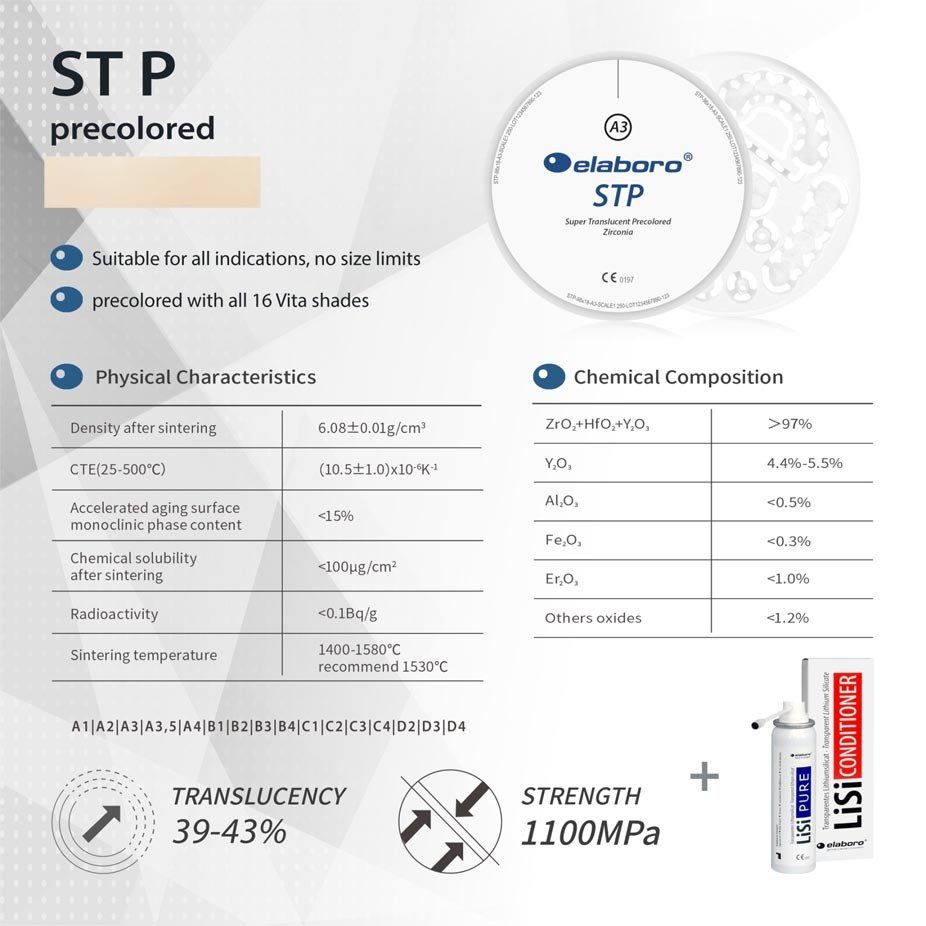

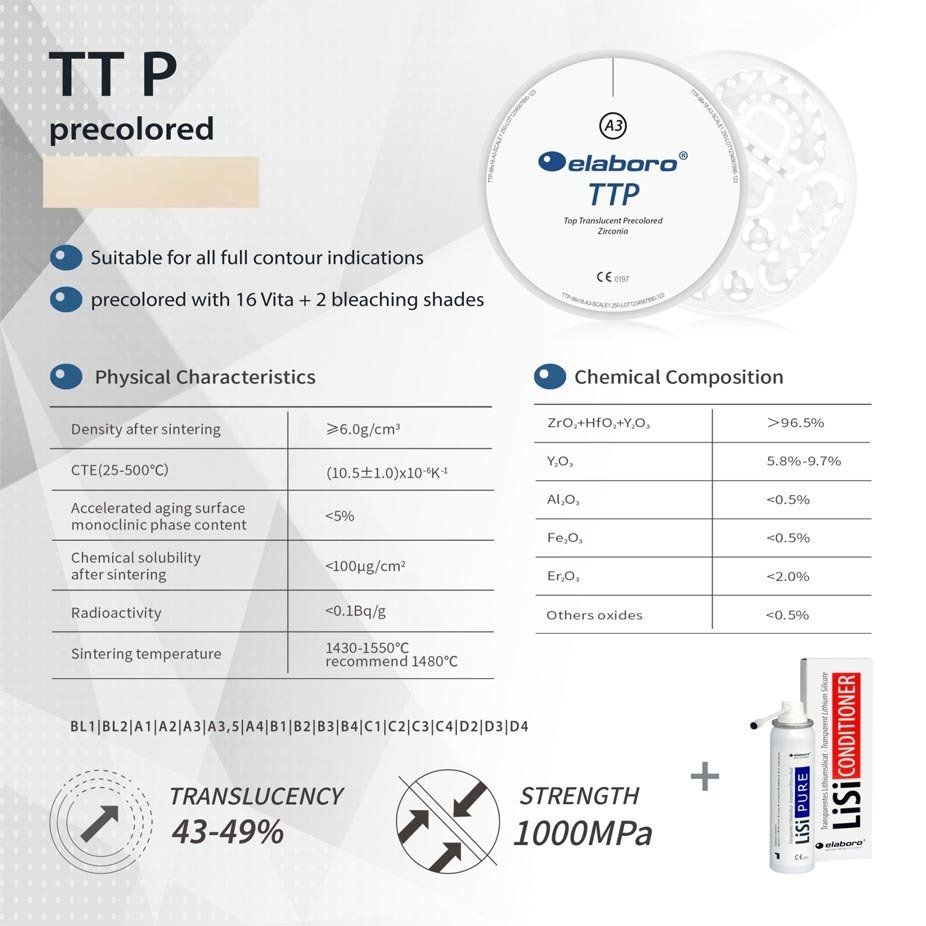

TTP Zirconia Blanks are characterized by their homogeneous coloring and maximum translucency.

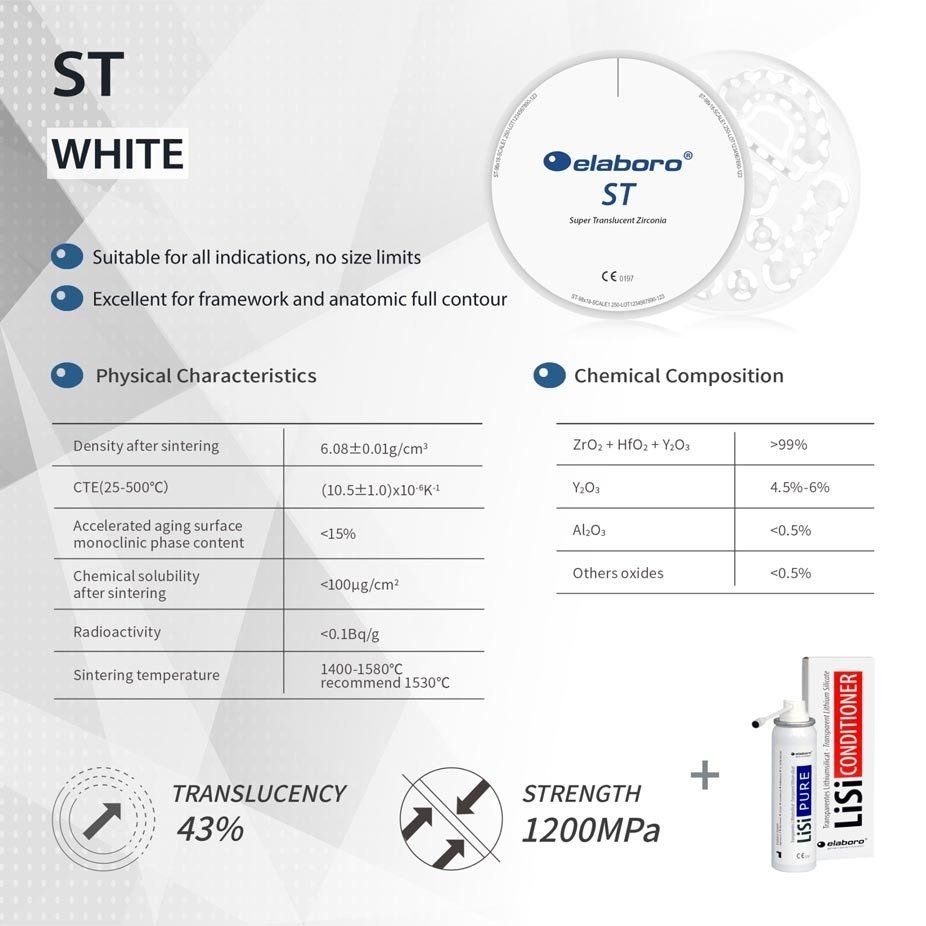

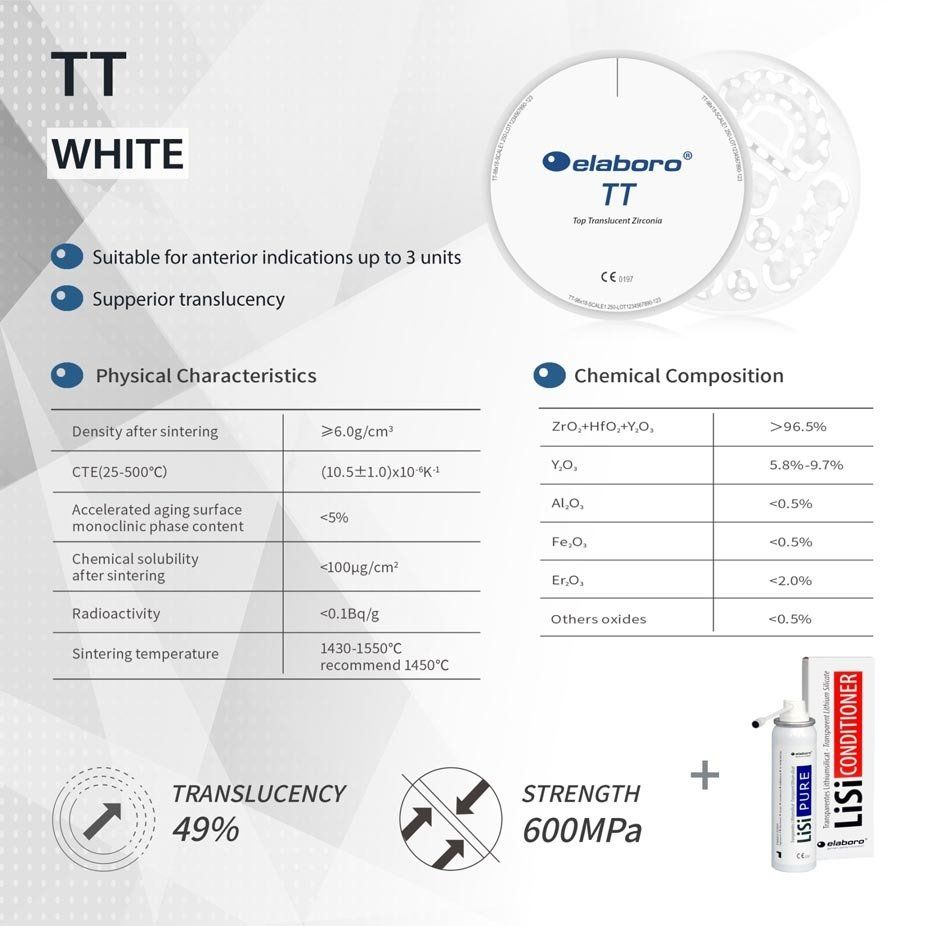

TT

White Zirconia

–

basic blank

for

Individual

Esthetic Concept

with

elaboro®

Coloring Fluids

in

16 colors and

individual

Effect

Fluids

for

dipping and

brushing.

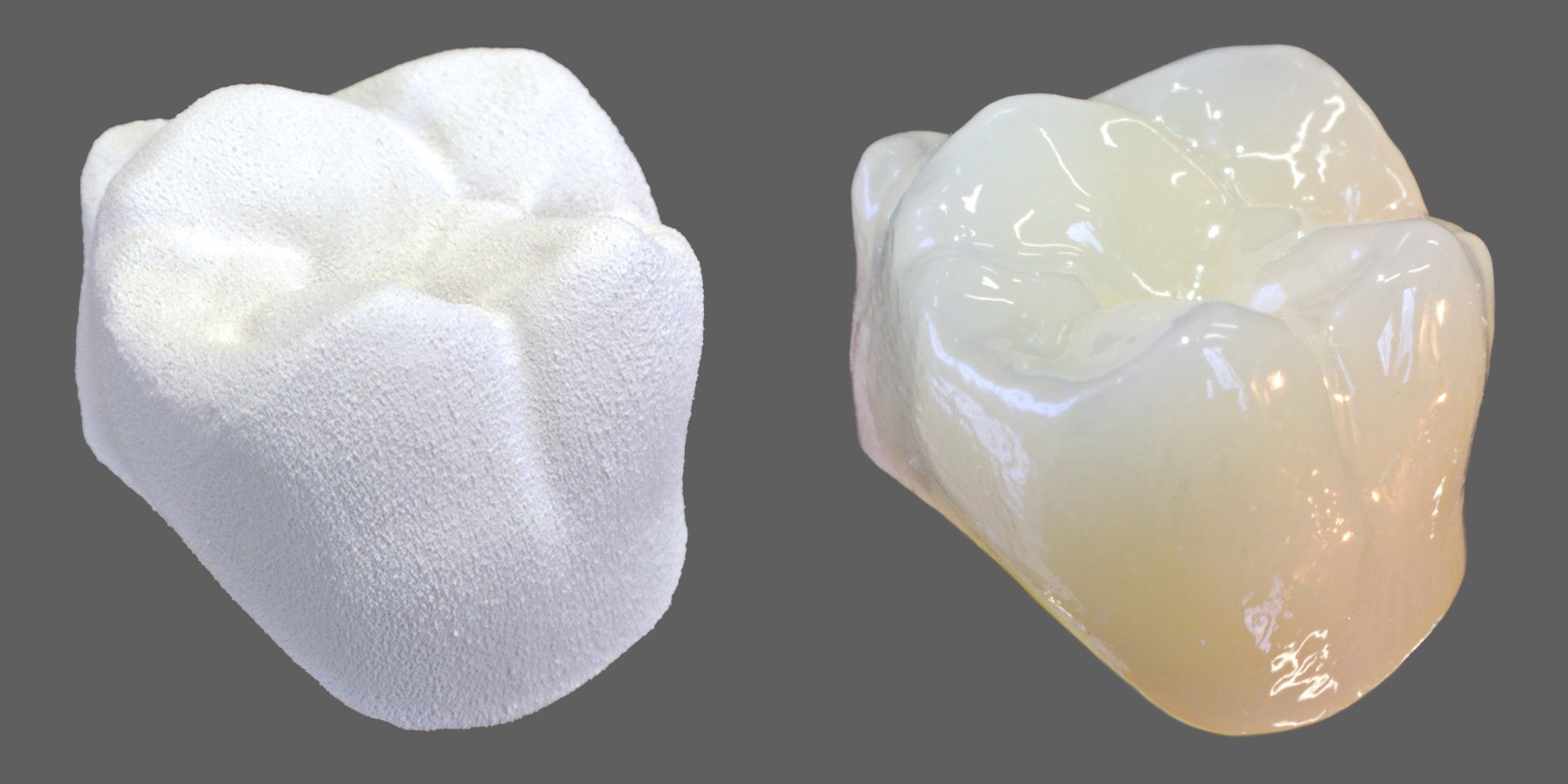

elaboro® LiSi Surface Finishing

Fusion of Function and Esthetics

In adhesive cementation, the residual tooth hard substance is stabilized without tension by adhesive bonding. Defect-oriented, i.e. minimally invasive, can be prepared without tension-indicating mechanical retention. The adhesive bond is non-positive. Adhesive cementation is therefore more "tolerant" with regard to the fit. Increased demands on the user and the lower moisture tolerance are more than eliminated by the improved mechanical and optical properties. Adhesive fastening materials, available in different tooth shades, play a key role in shaping the color perception of highly translucent ceramics and also allow a certain translucency. The pretreatment of the hard tooth substance and the zirconia restoration plays a decisive role in long-term success.

Master

the challenge with

elaboro®

LiSi CONDITIONER!

New Quality of Zirconia Adhesive Fastening

Documentation

as PDF-Download

• Info Leaflet elaboro® LiSi CONDITIONER

• Instruction for Use elaboro® LiSi PURE

• Instruction for Use elaboro® LiSi CONDITIONER

-1920w.png)